The pursuit of low-cost, quality housing has determined government programs and funded research activities with similar frameworks in wide-ranging settings. Often championed by large corporations or philanthropists much of this compiled research shaped and mapped out the construction industry’s progress. In the years following World War 2, in Sweden, large construction industry leaders such as Skanska financed the Home Building Research Corporation in an attempt to democratize cheaper but improved housing. This investigation considered modular coordination as the primordial standardization to bring about large quantities and streamlined production methods.

Architects Lennart Bergvall and Erik Dahlberg were charged with the task of reporting back to the Research Corporation with specific gauges and metrics to help reform housing production. Their reports became the basis of additional investigation and controls published by the Modular Building Group in the 1960s. Further, out of this research partnership, the architects founded AB Elementhus, a factory built housing system based on the basic principles of modular and dimensional coordination: the assembly of a few continuously produced and interchangeable building elements and parts.

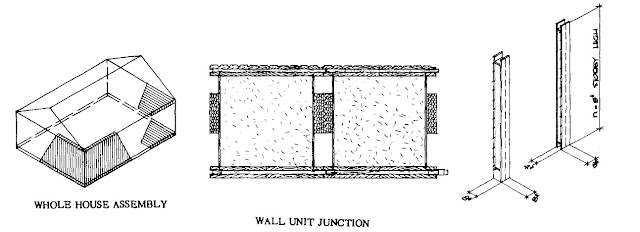

Inspired by previous and similar studies, principally Bemis’ 100mm (4-inch) building matrix, the Elementhus components used a 200mm module (8-inch). Nominal 200mm x 200mm vertical and horizontal box beams were developed to structure walls, floors and roofs. The box beams, rectangular prisms cut to varied lengths, were laminated from hardwood veneer plywood and a sawdust/woodchip insulating core. Each box beams’ extrados and intrados flange was tongue and grooved and simply attached with dowels. The kit included bearing and spanning units and shorter lengths for below or above windows or around other openings. The patented assembly method and dimensions regulated the whole modular grid for arranging housing patterns. The factory produced nearly three houses per day and a total of 18 000 housing units during its operation. An emblem of streamlined manufacturing processes with a minimum number of interchangeable parts, the process used 100% of all its timber, for the panels, their insulation and fuel for heating and running machinery. Elementhus idealized modular coordination and symbolizes the type of dimensional and modular theories that were applied to the problem of accessible housing.

|

| Elementhus components |

No comments:

Post a Comment