Industrialized building systems, the topic of abundant literature, are inspiring a new generation toward a revolution in construction. Accentuated by digital manufacturing concepts, modern processes can alter both design and building production. DfMA, «platform» methodologies, or offsite, are all discussed as innovative prefabrication theories improving construction’s stagnating productivity and have increased mainstream attention for preparing building chunks in factories.

Recent, significant venture capital investments have identified offsite as perhaps the next Klondike or at least the sole remaining sector to have escaped high value industrialization; According to many, construction industrialization’s day has finally come. Even architectural firms that have contested the standardization associated with factory produced architecture are suggesting prefab as a better design/building/business model.

Schemata workshop, a Seattle, USA based design firm has developed two systems that transcribe digital potentials for design. The first developed with manufacturer Dogwood industries is an integrated service core known as Middlemod. The consortium-based business, Building and Module Manufacturing LLC (BAMM) unites architects and fabricators in a limited liability partnership. The modular core is designed to fit into any construction system and can adapt to multiple spatial arrangements. The unit is planned to maximize factory preassembly, facilitate just-in-time delivery to any site with simple plug-and-play utility connections, and optimize virtual coordination. The MIddlemod concept sometimes also known as a combo-pod includes kitchen, bath, and utility room.

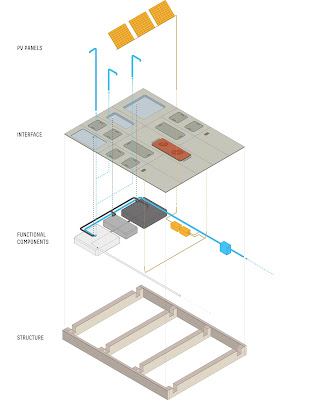

The firm’s other product is a component-based structural frame and kit that speeds up design by systematizing parts, construction, and assembly details from project to project. The steel skeletal and panelized building system includes envelope segments, windows, PV panels for energy production and mechanical distribution in a digital distributable format. The open-source methodology intends to bring affordability to housing production by multiplying the number of projects using the same parts, exploiting serial production. Schemata Workshop along with their partners envisioned this construction system to reduce waste at all project stages.

While promising in theory, the open-source concept applied to architecture is still relatively marginal. However, firms like Elemental, 369 pattern buildings and even Wikihouse share innovative building ideas and improve them through harvesting crowd iterations. The digital revolution applied to prefab suggests these platform-based directions to help the building sector at last adhere to industrialization’s promised advantages.

|

| left: Combo pod; right: Kit-of-parts |