Prefabrication and customized design have rarely converged. Effective production requires cultivating replicable patterns and designs to guarantee streamlined manufacturing. Personalization challenges are further enhanced when building systems are integrated or fitted out in a factory setting. Modular volumetric is an excellent case and point as big boxes are outfitted up to 70%. While advantageous for planning and climate-controlled task completion, it can certainly limit design freedom. Architects and industrialists have tried to address this difficulty through open systems.

Design limitations, project pipeline forecasting, upfront factory investments, along with greater transport and site staging constraints have produced contrasting results and have even sometimes led to superior overall costs. In opposition to building with big chunks, panelized surface elements equipped to various degrees, flat-packed and sequenced for onsite construction can provide more design freedom. Panels do require more intensive site work, however, this can be compensated by easy-to-assemble features. Fabricating modular, versatile, and complete panels can vary according to designs and are dimensionally less restrictive.

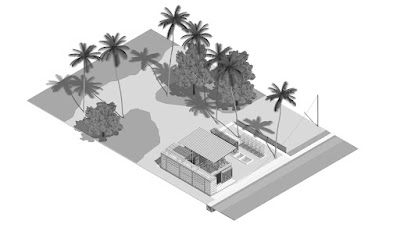

The MAAP House Company from Australia promotes this type of panelized construction as a way of simplifying transport and project completion. Panels can be used for floors, walls, and roofs in a type of planar shell kit strategy. MAAP panels remain fully demountable after assembly which makes the building envelope 100% relocatable and reusable. The stressed-skin, lightweight partitions are composed of a cold formed steel skeletal core lined with magnesium oxide board making the system fireproof and mold resistant. Each panel is created in line with the company’s preset dimensional standards, and they can be put together by one or two people in any geographical context.

Like many other panel-based systems, the MAAP house components are delivered to fit seamlessly and form a weatherproof building skin. Limitations include site intensive furnishing of all other building systems. To commercialize complete kits, MAAP has developed wet rooms, kitchens and bathrooms, as completed volumes, pods or brought to site as cartridge-like mechanical elements. This hybrid approach is promoted by the company as resolving transport issues. The flat pack and pods approach also makes their system adaptable to any architectural design.

|

| Flat-packed panels from https://www.maaphouse.com/bettermodulartransport.html |